Embossed Aluminium Honeycomb Panel for Producing Tonneau Tri-Fold Cover

Aluminium Honeycomb Sandwich Panels with embossed finish for Special Decoration and ApplicationsEmbossed surface Aluminu

Basic Info

| Material | Aluminum Alloy |

| Performance | Light |

| Function | Interior and Exterior Decoration |

| Aperture | 8mm |

| Level | A |

| Application | Interior Decoration |

| Thickness | 6mm to 300mm |

| Features | Lightweight, Strong, Customized, Good Flatness |

| Surface Finish | PVDF/PE/Powder Coating, Anodizing |

| Color | Ral Colors, Stone Colors, Wood Colors |

| Warranty | 15 Years |

| Delivery Time | 15-35 Days |

| Uses | Building Decoration, Floor, Furniture, Partition |

| Transport Package | Wooden Box |

| Specification | 1220x2440mm or customized sizes, max 2500x12500mm |

| Trademark | HWSTRONGER |

| Origin | China |

| HS Code | 7606129000 |

| Production Capacity | 150000-200000sqm/Year |

Product Description

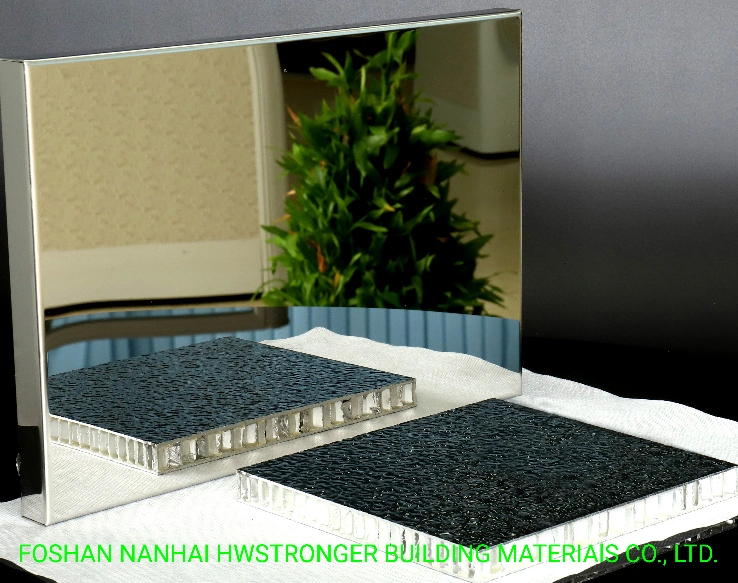

Aluminium Honeycomb Sandwich Panels with embossed finish for Special Decoration and ApplicationsEmbossed surface Aluminum is a superior material with embossed patterns on the surface, the embossed patterns are molded process and can be designed as per customer's request.Available thickness: 10mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 70mm, 80mm,90mm, 100mm, 200mm etc.Available colors: Silver, grey, champagne, gold, blue, green, red, yellow, white, black, brown etc.Embossed patterns: as per customer's designs

Very Lightweight but High Stiffness Aluminum Honeycomb Panel

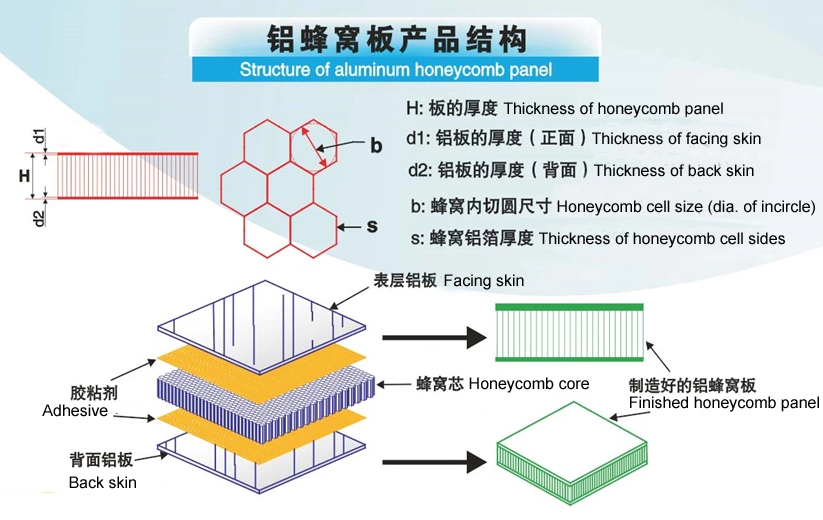

How the Embossed Aluminum Honeycomb Panel is made?The embossed Aluminum honeycomb panel is typically made of 5 layers: embossed Aluminum top skin, adhesive, Aluminum honeycomb core, adhesive and back mill finish Aluminium or same skin. The thickness of honeycomb panels can be changed with a variety of honeycomb cores that are available as per design requirements for materials and cell sizes.The illustration of honeycomb panel composition:Features and Advantages

The honeycomb panel is made with Honeycomb structure core inside, the honeycomb structures that have the geometry of a honeycomb to allow the minimization of the amount of used material to reach minimal weight and minimal material cost. The geometry of honeycomb structures can vary widely but the common feature of all such structures is an array of hollow cells formed between thin vertical walls. The cells are often columnar and hexagonal in shape. A honeycomb shaped structure provides a material with minimal density and relative high out-of-plane compression properties and out-of-plane shear properties.

• Low weight. Much llower weight than single metal panel in the same thickness.

• High stiffness and high impact strength.• Good flatness.• Good self-recovering surface to stay long lasting color.• Easy to fabricate and install• Recyclable• Environment-friendly material.• Sound proofing and thermal insulation.• Wide variety of optional colors: RAL colors, wood grain colors, marble or granite grain colors, chameleon mixed colors etc.• Brushed and anodised aluminum finishes are also available.• Wide range of uses: building decoration, shipbuilding, furnitures, aerospace or automobile.• Flexible in thickness of honeycomb panels: 6mm, 8mm, 10mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 100mm, 200mm etc. available.

Applications:

- Architectural Building Cladding and decoration

- Architectural Rainscreen Facades

- Partitions and walls.

- Lightweight interior architectural panels

- Tables and furnitures.

- Aerospace, Marine & Transport Flooring, Walls & Partitions

- Silk Screen Printing Tables

- CNC Vacuum Bases

- Lightweight Floors, Walls, Ceilings, etc

- Special Purpose Panel Design

Packing: Palletized wooden box

Send to us